Discover how RAMs in construction are revolutionising project safety and efficiency, transforming the way we manage building site risks and compliance.

What are RAMs in Construction?

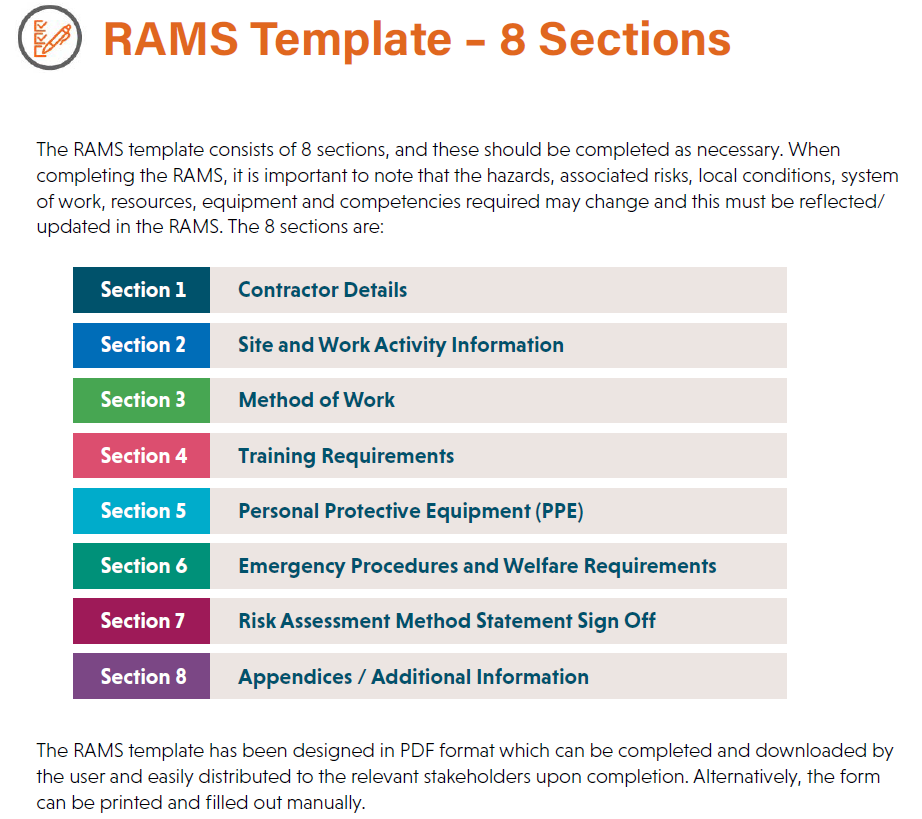

RAMs (Risk Assessment and Method Statements) are crucial documents that form the backbone of construction site safety management in the UK. These comprehensive documents serve as both a legal requirement and a practical guide for ensuring workplace safety. Recent studies show that proper implementation of RAMs can reduce workplace incidents by up to 75%, making them an indispensable tool in modern construction practices. At their core, RAMs consist of two main components: a detailed risk assessment that identifies and evaluates potential hazards, and a method statement that outlines specific procedures for safely executing construction tasks. These documents work in tandem to create a robust safety framework that protects workers, visitors, and the public while ensuring project efficiency.

The Anatomy of a Risk Assessment

- Hazard Identification: Systematic evaluation of potential dangers in the workplace, including physical, chemical, and environmental risks

- Risk Evaluation: Assessment of likelihood and severity of identified hazards using a standardised matrix

- Control Measures: Implementation of the hierarchy of controls (elimination, substitution, engineering controls, administrative controls, PPE)

- Review Process: Regular assessment and updates to ensure continued effectiveness

- Documentation: Detailed recording of all findings and implemented measures

Method Statements: Creating Clear Safety Protocols

Method statements transform risk assessments into actionable protocols, providing step-by-step guidance for safe task execution. According to the Health and Safety Executive (HSE), well-crafted method statements can improve work efficiency by up to 30% while maintaining optimal safety standards. These documents detail specific procedures, required equipment, necessary qualifications, and emergency protocols. They must be clear, concise, and easily understood by all workers, regardless of their experience level. Modern method statements often incorporate visual elements such as diagrams and flowcharts to enhance comprehension and ensure consistent application across the workforce.

Legal Requirements and Compliance

In the UK construction industry, RAMs are not just best practice—they’re a legal necessity under the Health and Safety at Work Act 1974 and the Management of Health and Safety at Work Regulations 1999. Non-compliance can result in fines of up to £20,000 in magistrates’ courts or unlimited fines in crown courts. Companies must ensure their RAMs are:

- Regularly updated and reviewed

- Specific to each task and site

- Readily available to all relevant parties

- Compliant with current regulations

- Properly communicated to all workers

Implementing Effective RAMs in Practice

Successful implementation of RAMs requires a systematic approach and full commitment from all stakeholders. Research indicates that companies with comprehensive RAMs implementation programmes experience 45% fewer workplace accidents. Key steps include thorough staff training, regular reviews, and effective communication channels. Project managers must ensure that RAMs are living documents that evolve with the project, incorporating feedback from workers and adapting to changing site conditions. Regular toolbox talks and safety briefings help maintain awareness and compliance throughout the project lifecycle.

Common Challenges and Solutions

- Challenge: Poor communication – Solution: Implement digital sharing platforms and regular briefings

- Challenge: Outdated documentation – Solution: Establish regular review schedules and update triggers

- Challenge: Resistance to compliance – Solution: Enhance training and demonstrate practical benefits

- Challenge: Complex documentation – Solution: Simplify language and include visual aids

- Challenge: Time constraints – Solution: Use standardised templates and digital tools

Digital Innovation in RAMs Management

The construction industry is witnessing a digital revolution in RAMs management. Digital adoption in construction safety management has increased by 65% since 2020, with cloud-based systems and mobile applications leading the way. Modern digital solutions offer real-time updates, automated notifications, and integrated risk management platforms. These innovations enable better tracking, improved accessibility, and more efficient compliance monitoring. Mobile apps now allow workers to access RAMs documentation instantly, report issues in real-time, and receive immediate updates about changing site conditions.

Best Practices for RAMs Success

To maximise the effectiveness of RAMs, construction professionals should follow these proven best practices:

- Involve workers in the development process to ensure practical applicability

- Use clear, jargon-free language

- Include site-specific details and photographs

- Regular review and updates based on site feedback

- Maintain comprehensive training records

- Implement a digital management system for better tracking

Moving Forward: The Future of Construction Safety

The future of RAMs in construction is evolving rapidly with technological advancement and increased focus on worker safety. Industry experts predict a 40% increase in the adoption of AI-powered risk assessment tools by 2025. Emerging trends include virtual reality training simulations, IoT sensors for real-time hazard detection, and blockchain for transparent safety record-keeping. These innovations promise to make RAMs more dynamic, predictive, and effective in preventing accidents and ensuring compliance. As the construction industry continues to embrace digital transformation, RAMs will become increasingly integrated with project management systems, creating a more comprehensive and proactive approach to site safety.

FAQ

Why are rams so important?

RAM is used for immediate data storage and retrieval. Your RAM can process information significantly faster than data on a hard disk — twenty to a hundred times faster, depending on the specific hardware and task.

What is rams in engineering?

The RAMS (Reliability, Availability, Maintainability and Safety) disciplines are a set of tools that make it possible to ensure that a product, process or system fulfils the mission for which it was designed, all under the conditions of reliability, maintainability, availability and well-defined safety.

What were rams used for?

Rams proved effective weapons of war because at the time wall-building materials such as stone and brick were weak in tension, and therefore prone to cracking when impacted with force. With repeated blows, the cracks would grow steadily until a hole was created.

What is rams used for?

Random-access memory, or RAM, is one of the most important parts of your computer. It provides high-speed, short-term memory for your computer’s CPU. The amount of computer memory you need depends on what you use your computer for, but 12 GB of RAM is a good general minimum standard.

What do you need rams for?

In summary the purpose of RAMS is to ensure health and safety, identify hazards and risks associated with a task (etc) and provide suitable and sufficient control measures to control risk assessment and further provide a safe system of work/step-by-step instructions to persons carrying out the task etc. to mitigate the …

Sources

[1] https://www.hsdept.co.uk/services/rams-risk-assessments-method-statement/

[2] https://humanfocus.co.uk/blog/what-are-rams-in-construction/

[3] https://www.hsa.ie/eng/your_industry/construction/besmart_ie_for_construction/risk_assessment_method_statement_rams_template_and_guidance/

Leave a Reply