Discover how torsion construction techniques are revolutionising modern building stability, transforming the way we approach structural integrity in contemporary architecture.

In today’s rapidly evolving construction landscape, understanding and managing torsional forces has become increasingly crucial for ensuring building stability and longevity. With modern architectural designs becoming more complex and ambitious, the need for sophisticated torsion management solutions has never been more pressing.

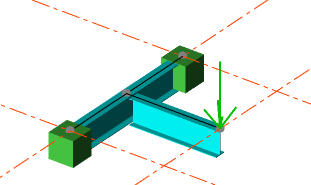

The Fundamentals of Torsion in Construction

Torsion in construction refers to the twisting force that acts on structural elements, potentially causing rotation around their longitudinal axis. In the UK construction industry, where building regulations are becoming increasingly stringent, understanding these forces is paramount. Recent studies indicate that up to 40% of structural failures can be attributed to inadequate consideration of torsional forces during the design and construction phases.

What is Torsional Force?

Torsional force, or torque, occurs when an applied force creates a twisting effect on a structural element. In building construction, this phenomenon is particularly relevant in:

- Multi-storey buildings with irregular floor plans

- Structures with eccentric loading conditions

- Buildings with asymmetrical designs

- Long-span architectural features

- Structures in areas with high wind loads

Critical Components in Torsion Management

Effective torsion management relies on several key structural elements and design considerations:

- Shear walls and core systems

- Moment-resisting frames

- Strategic placement of bracing systems

- Careful consideration of material properties

- Proper connection detailing

Implementation of Torsion Construction Techniques

Modern torsion construction techniques require a comprehensive approach that combines traditional engineering principles with innovative solutions. Recent industry data shows that projects implementing advanced torsion management systems have experienced a 30% increase in structural efficiency. This improvement directly translates to enhanced building performance and reduced maintenance costs over time.

Design Considerations

When planning for torsional forces, architects and engineers must consider:

- Building geometry and configuration

- Load distribution patterns

- Environmental factors specific to the UK climate

- Soil conditions and foundation requirements

- Future adaptability needs

Material Selection and Specifications

The choice of materials plays a crucial role in torsional resistance. Modern construction projects increasingly rely on:

- High-strength structural steel

- Reinforced concrete with specific mix designs

- Composite materials for enhanced performance

- Innovative connection systems

- Smart materials with monitoring capabilities

Innovation in Torsion Construction Methods

The construction industry has witnessed significant advancements in torsion management techniques. Industry reports indicate a 25% increase in the adoption of innovative torsion construction methods over the past five years, particularly in urban development projects across the UK.

Modern Approaches to Torsional Stability

Contemporary solutions include:

- Dynamic damping systems

- Advanced structural monitoring tools

- Integrated design software

- Smart material applications

- Predictive maintenance systems

Technology and Tools

The digital transformation of construction has introduced sophisticated tools for torsion analysis and management:

- 3D structural analysis software

- Building Information Modelling (BIM) integration

- Real-time monitoring systems

- Artificial Intelligence for predictive analysis

- Virtual reality for design validation

Best Practices in Torsion Construction

Implementing best practices in torsion construction requires a systematic approach that encompasses design, construction, and maintenance phases. Studies show that projects following established best practices experience 45% fewer structural issues related to torsional forces.

Quality Control Measures

Ensuring proper implementation requires rigorous quality control protocols:

- Regular structural inspections

- Material testing and certification

- Construction sequence monitoring

- Documentation and reporting systems

- Third-party verification processes

Maintenance and Monitoring

Long-term stability requires ongoing attention to:

- Regular structural assessments

- Preventive maintenance schedules

- Performance monitoring systems

- Response planning for potential issues

- Documentation of structural behaviour

Future of Torsion Construction

The future of torsion construction is being shaped by emerging technologies and sustainable practices. Industry forecasts predict a 35% growth in the adoption of advanced torsion construction techniques by 2025, driven by increasing demands for structural efficiency and sustainability.

Emerging Trends

Key developments in the field include:

- Integration of smart sensors and IoT devices

- Advanced materials with self-healing properties

- Automated construction processes

- Climate-responsive design solutions

- Enhanced simulation capabilities

Sustainable Solutions

Environmental considerations are increasingly driving innovation in torsion construction:

- Low-carbon materials and methods

- Energy-efficient structural solutions

- Waste reduction strategies

- Recyclable building components

- Green construction practices

Expert Insights and Recommendations

Industry experts emphasize the importance of comprehensive planning and execution in torsion construction. Success relies on:

- Early involvement of structural engineers

- Regular team collaboration and communication

- Continuous professional development

- Implementation of lessons learned

- Adaptation to emerging technologies

As the construction industry continues to evolve, understanding and implementing effective torsion construction techniques becomes increasingly vital for ensuring structural stability and longevity. By following these guidelines and staying informed about industry developments, construction professionals can deliver projects that meet both current requirements and future challenges in the built environment.

FAQ

What exactly is torsion?

Let’s explore what happens when we apply torque to a circular bar.

How to remove torsion in a building?

Steel strips placed opposite to the stiffness irregularity balances the irregularity as it reduces eccentricity between center of stiffness and center of mass whereas the strips provided along the full length in one direction can eliminate torsion.

Sources

[1] https://www.torsionconstruction.co.uk

[2] https://www.constructionenquirer.com/2025/09/05/torsion-developments-racks-up-record-profits/

[3] https://torsion-care.co.uk

Leave a Reply