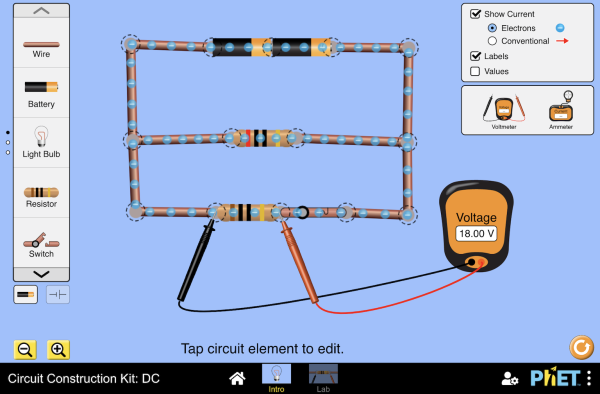

Transform your electrical projects with a circuit construction kit DC that professionals trust – discover the secrets to perfect circuit building every time.

Understanding DC Circuit Construction Fundamentals

In today’s rapidly evolving electrical landscape, mastering DC circuit construction is essential for both professionals and enthusiasts. Circuit construction kits serve as invaluable tools for learning, prototyping, and developing electrical projects. These kits provide a safe, controlled environment for experimenting with electrical concepts while adhering to British Standards (BS 7671:2018+A2:2022). Before diving into circuit construction, it’s crucial to understand that safety comes first – always ensure proper insulation, use appropriate personal protective equipment (PPE), and work in a well-ventilated area. The fundamental equipment needed includes a reliable multimeter, wire strippers, pliers, screwdrivers, and a breadboard for prototyping.

Essential Components of a DC Circuit Construction Kit

A comprehensive DC circuit construction kit comprises several vital components, each serving specific functions in circuit design. Understanding these components is crucial for successful project completion:

- Power Sources: DC batteries (ranging from 1.5V to 9V), power supplies, and solar cells for sustainable applications

- Resistors: Various resistance values (100Ω to 1MΩ) for current control and voltage division

- Capacitors: Both electrolytic and ceramic types for energy storage and filtering

- Semiconductors: Diodes, LEDs, and transistors for current control and switching

- Connectors: Jumper wires, crocodile clips, and terminal blocks

- Measurement Devices: Digital multimeters for voltage, current, and resistance measurements

Setting Up Your Workspace for Circuit Construction

Creating an efficient workspace is paramount for successful circuit construction. Begin by selecting a well-lit area with adequate ventilation and a stable work surface. According to recent HSE guidelines, proper workspace organisation can reduce accidents by up to 73%. Essential elements include:

- Anti-static mat to protect sensitive components

- Component organiser with clearly labeled compartments

- Adequate lighting with at least 500 lux brightness

- Clean, uncluttered workspace with easy access to tools

- First aid kit and fire safety equipment nearby

Building Basic DC Circuits: Step-by-Step Guide

Mastering basic DC circuits requires a systematic approach. Start with simple circuits and progressively move to more complex designs. Begin with a basic LED circuit: connect the positive terminal of a 9V battery through a 470Ω resistor to the anode of an LED, then complete the circuit by connecting the LED’s cathode to the battery’s negative terminal. For parallel circuits, maintain identical voltage across components while dividing current. In series circuits, current remains constant while voltage divides across components. Always verify connections before applying power and use a multimeter to confirm proper voltage and current levels.

Advanced Circuit Construction Techniques

As your expertise grows, explore more sophisticated circuit designs. Advanced techniques include implementing multiple power sources for varied voltage requirements, creating complex switching networks using relays and transistors, and incorporating protection circuits. Consider these professional approaches:

- Voltage regulation circuits for stable power delivery

- Current limiting protection circuits

- Pulse width modulation (PWM) for motor control

- Temperature compensation circuits

- Signal conditioning and filtering networks

Testing and Troubleshooting DC Circuits

Effective testing and troubleshooting are critical skills for successful circuit construction. According to industry statistics, over 60% of circuit failures can be attributed to poor connections or component mismatches. Implement a systematic testing approach:

Begin with visual inspection for obvious faults, measure voltage at key points, verify current flow through critical paths, and check for expected resistance values. Common issues include reversed polarity, cold solder joints, and incorrect component values. Use oscilloscopes for complex signal analysis and thermal imaging for identifying hot spots in power circuits.

Best Practices and Professional Tips

Industry experts recommend following these best practices for optimal circuit performance and reliability:

- Use proper wire gauge based on current requirements

- Implement strain relief for all connections

- Document circuit modifications and testing results

- Maintain regular calibration of testing equipment

- Follow proper ESD (Electrostatic Discharge) procedures

Practical Applications and Projects

Apply your DC circuit construction skills to real-world projects that demonstrate practical applications. Popular projects include:

- Solar-powered LED garden lights with automatic darkness detection

- Battery charge controllers for renewable energy systems

- Smart home automation circuits

- Temperature-controlled cooling systems

- Emergency backup power supplies

Conclusion: Mastering Your DC Circuit Construction Skills

Mastering DC circuit construction requires dedication, practice, and adherence to proper techniques. By following this comprehensive guide, you’ve gained essential knowledge about component selection, workspace setup, construction techniques, and troubleshooting methods. Remember to prioritise safety, maintain organised documentation, and continuously update your knowledge as technology evolves. Whether you’re a hobbyist or professional, these skills form the foundation for successful electrical projects in the UK’s dynamic construction industry.

Sources

[1] https://excelschools.net/en/simulation/circuit-construction-kit-dc.html

[2] https://www.compadre.org/portal/items/Relations.cfm?ID=2465

[3] https://www.youtube.com/watch?v=9xL9rzZL08g

Leave a Reply