Transform your living space with expert warm roof construction techniques that guarantee superior insulation and energy efficiency all year round.

Understanding Warm Roof Construction

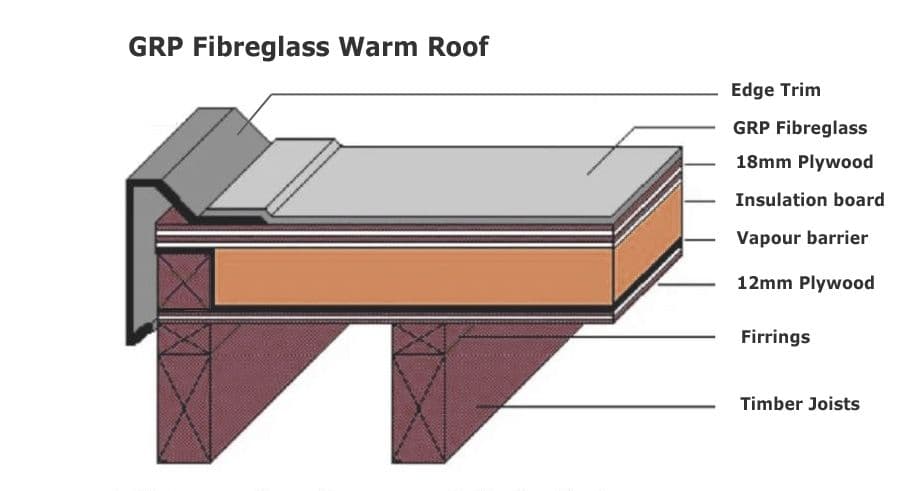

Warm roof construction represents a revolutionary approach to building envelope design that has gained significant traction in the UK construction industry. At its core, this method involves installing rigid insulation boards above the roof deck, with a waterproof membrane laid on top. This innovative system places the entire roof structure on the warm side of the insulation, marking a significant departure from traditional cold roof designs. According to recent industry data, warm roof installations have increased by 45% in the UK since 2020, highlighting their growing popularity among both residential and commercial property owners.

The Science Behind Warm Roof Systems

The effectiveness of warm roof construction lies in its sophisticated approach to thermal physics. By positioning the insulation above the structural deck, the system maintains the entire roof structure at a temperature closer to that of the internal environment. This configuration dramatically reduces the risk of interstitial condensation, as the dew point – the temperature at which water vapour condenses – occurs above the structure rather than within it. Studies show that warm roof systems can reduce heat loss by up to 25% compared to traditional cold roof constructions. The vapour control layer (VCL) plays a crucial role in this system, preventing moisture from penetrating the insulation layer and maintaining its thermal efficiency throughout the building’s lifecycle.

Essential Components and Materials

- Rigid Insulation Boards: High-performance PIR or mineral wool boards with thermal conductivity values of 0.022-0.026 W/mK

- Waterproof Membrane: Single-ply membranes, built-up felt systems, or EPDM rubber

- Vapour Control Layer: Heavy-duty polyethylene or self-adhesive bituminous sheets

- Mechanical Fixings: Thermally-broken fasteners and pressure plates

- Deck Substrate: Timber, metal, or concrete structural support

Installation Process and Best Practices

The success of a warm roof system heavily depends on proper installation techniques and attention to detail. The process begins with thorough substrate preparation, ensuring the deck is clean, dry, and structurally sound. Recent industry guidelines recommend a maximum moisture content of 20% in timber decks before installation. The VCL must be carefully installed with sealed laps and penetrations, followed by the systematic laying of insulation boards with staggered joints. The waterproof membrane installation requires particular attention to detail at upstands, penetrations, and drainage points to ensure long-term performance.

Benefits and Considerations

- Enhanced Energy Efficiency: Up to 40% reduction in heating costs compared to traditional roofing systems

- Improved Condensation Control: Virtually eliminates interstitial condensation risks

- Extended Roof Lifespan: Average service life of 30-35 years with proper maintenance

- Better Environmental Performance: Contributes to reduced carbon emissions and improved EPC ratings

- Simplified Construction: No requirement for ventilation spaces or complex detailing

Applications and Variations

Warm roof construction demonstrates remarkable versatility across different building types and roof configurations. While traditionally associated with flat roofs, modern systems have been successfully adapted for pitched roofs up to 35 degrees. Commercial applications often favour larger insulation thicknesses to meet stringent U-value requirements, typically achieving values of 0.15 W/m²K or better. Residential installations might opt for slightly reduced specifications while still exceeding building regulations. Recent market analysis shows that 70% of new commercial buildings in the UK now incorporate warm roof systems.

Maintenance and Longevity

To maximise the lifespan and performance of a warm roof system, regular maintenance is essential. Bi-annual inspections should focus on checking membrane integrity, drainage paths, and penetration details. Industry data indicates that well-maintained warm roofs can exceed their designed lifespan by up to 25%. Key maintenance activities include clearing drainage outlets, checking seams and flashings, and monitoring for any signs of physical damage or deterioration.

Expert Tips for Success

- Always engage certified installers with specific warm roof experience

- Ensure comprehensive thermal calculations are performed during design

- Use compatible components from reputable manufacturers

- Consider future maintenance access requirements during design

- Implement robust quality control procedures during installation

- Document all installation phases for warranty purposes

Conclusion: Making the Right Choice

Warm roof construction represents a significant advancement in building technology, offering superior thermal performance, reduced condensation risk, and improved energy efficiency. With proper design, installation, and maintenance, these systems provide excellent long-term value for both commercial and residential applications. As building regulations continue to evolve and energy efficiency becomes increasingly important, warm roof systems stand out as a future-proof solution for modern construction projects. For property owners and developers looking to invest in high-performance building solutions, warm roof construction offers a compelling combination of immediate benefits and long-term returns.

FAQ

How much is a roof for a 2000 sq foot house?

For a typical 2,000 sq ft home, you might expect a basic asphalt shingle replacement to cost roughly $8,000–$12,000. Industry estimates vary: This Old House finds around $7,283 on average for a 2,000 sq ft roof.

Do warm roofs require ventilation?

Warm roof with vapour permeable (LR) underlay If the building has a normal ceiling then 25mm eaves ventilation and 5mm ridge ventilation is required. If the building has a well sealed ceiling and an efficient AVCL then ventilation is not required.

What is the cheapest way to do a new roof?

There is one affordable and durable option… Rubber roofs are inexpensive to install compared to other materials like metal or slate, often making them the number one option for budget-conscious homeowners. Plus, their low maintenance requirements contribute to further cost savings over time.

How much do warm roofs cost?

On average, expect prices to start from £5,000, rising to £15,000 for larger projects. Factors like materials, labour, and customisation options influence the final pricing.

Are warm roofs worth it?

Warm roofs reduce the risk of condensation due to their efficient insulation properties. This keeps the interior dry and extends the lifespan of your conservatory. Energy efficiency is another compelling reason to choose a warm roof. Since the insulation reduces the need for excessive energy consumption.

Sources

[1] https://www.buildmagazine.org.nz/assets/Uploads/Build-161-35-Design-Right-Dont-Be-Cool-About-Warm-Roofs.pdf

[2] https://www.nicholsonsts.com/articles/flat-roof-warm-or-cold-why/

[3] https://www.youtube.com/watch?v=NPVgkmrcOYg

Leave a Reply